On July 23, 2025, the Navy released the results of its pilot study to determine if injecting a specialized carbon solution into the ground would block hazardous PFAS chemicals from migrating into the Oakland Estuary from Alameda Point.

The area at issue, a stone’s throw from the estuary, had once been used by Navy firefighters to practice putting out fires with firefighting foam that contained PFAS chemicals. Scientists have figured out a way to contain, but not destroy, these hazardous chemicals. Follow-up groundwater samples show that the carbon barrier achieved between 99 percent and 100 percent reduction in PFAS moving beyond the barrier.

Because the 15-foot-deep carbon barrier has proven exceptionally effective during the pilot study, a deeper soil and groundwater testing plan has been designed.

The Navy is embarking on a new round of testing at greater depth because previous groundwater samples indicate that PFAS is present at depths below 15 feet and up to 35 feet deep. The Phase II PFAS investigation will begin taking groundwater samples in August, followed by three more sampling events over the next year. After the sampling and lab analysis is completed, it will take another year to draw conclusions and make recommendations as to whether the carbon barrier needs to be extended deeper.

How the PFAS-blocking system works

Cleaning up PFAS contamination has been a challenge because the compound is virtually impossible to destroy, which is why it has been dubbed a “forever chemical.” Since it can’t be broken up and rendered harmless in soil and groundwater, the next best thing is isolating it, also known as sequestering, and preventing it from moving into waterways and groundwater aquifers. That’s where a form of charcoal—activated carbon—comes in. PFAS chemicals coming in contact with activated carbon become permanently bonded to the carbon.

The process of trapping the PFAS in a carbon matrix is called adsorption, which means it is locked together like Velcro® and won’t come loose. It sounds like a similar process called absorption, which is what a cleaning sponge will do. But dirt absorbed into a sponge can be rinsed out.

While the in-ground carbon filter concept is elegantly simple, Regenesis, the manufacturer of the product used at Alameda Point, had to address two important challenges before implementing the system.

First, the carbon molecules had to be ground extremely fine—to the size of red blood cells at 1 to 2 microns—so that they would disperse evenly through openings between soil particles and coat the soil particles like a blanket.

A similar form of charcoal, called granulated activated charcoal, is used for such applications as large-scale municipal water treatment systems, aquariums, and coffee water filters, but the grain size of up to 300 microns makes it unworkable for injecting into soil for contamination treatment.

The second challenge was that simply mixing superfine charcoal dust with water and pumping it into the ground led to clumping of the product. To allow for uniform dispersion and no clumping, Regenesis developed a special biodegradable polymer to mix with the powdered charcoal. This proprietary mixture is called a colloid, in which one substance is suspended in another, hence the name colloidal activated carbon.

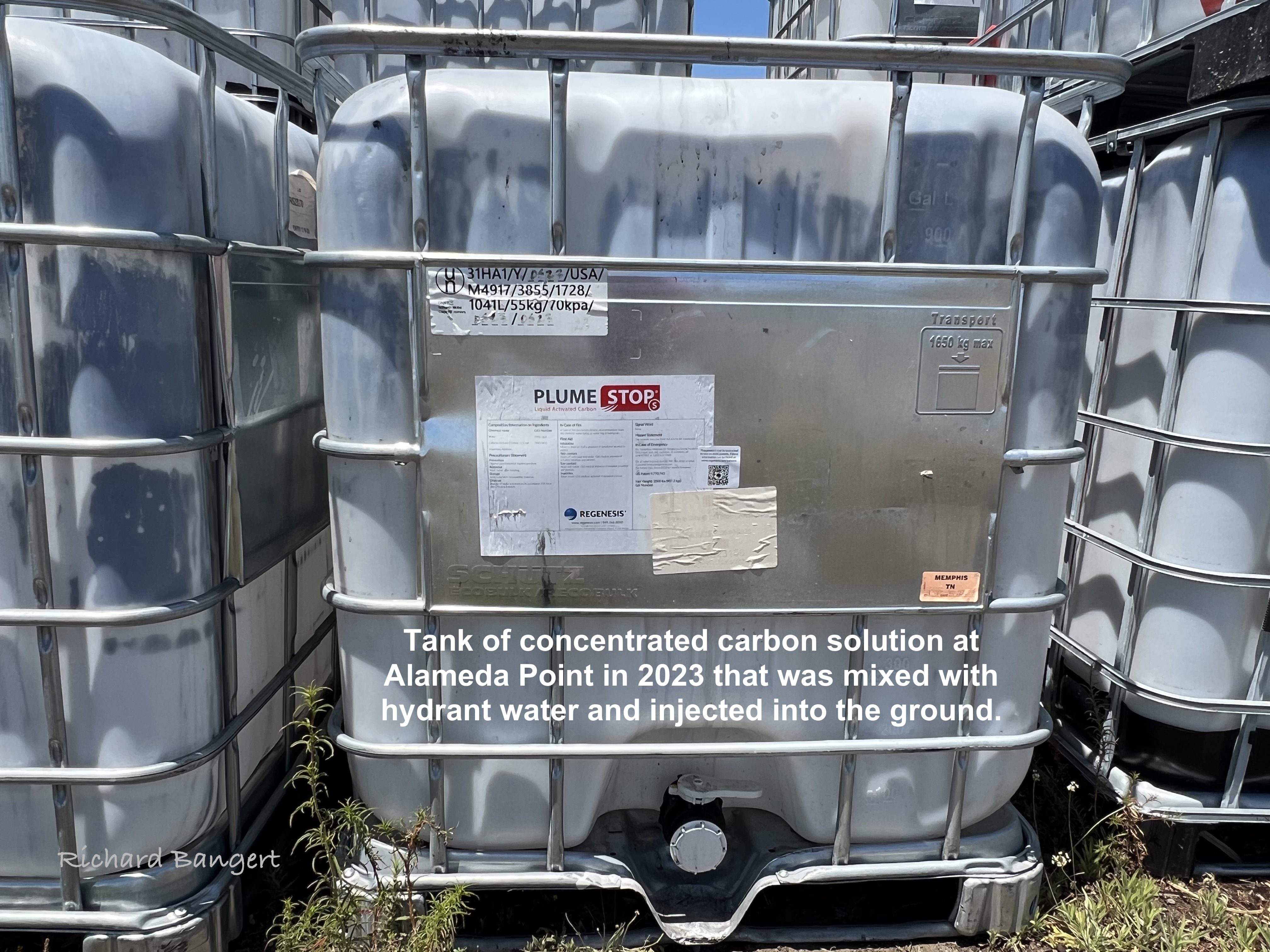

In 2023 during the pilot study, some 19,000 gallons of the Regenesis product called PlumeStop® were delivered to the site in 275-gallon tanks.

From June 21 to July 31, 2023, the product was mixed on-site with hydrant water in a trailer and injected at 288 different points along a 720-foot strip parallel to the shoreline. The company started at a depth of 15 feet and worked their way up. “This ‘bottom-up’ injection approach, performed in five 3-foot intervals per boring, maximized contact between the CAC [Colloidal Activated Carbon] and PFAS-contaminated groundwater,” states the company in a short presentation on the Regenesis website.

As groundwater naturally flows toward the shoreline and passes through the 15-foot vertical carbon barrier, PFAS molecules become trapped. The ink-black product is considered food-grade and harmless to the environment.

A draft report showing the results and recommendations of the Phase II PFAS investigation is expected by July 2027.

Further reading:

“Navy to lock down PFAS in groundwater with carbon,” Alameda Point Environmental Report, November 19, 2022.

“PFAS Explained,” U.S. Environmental Protection Agency, August 27, 2024.

The Ink-Black Product Is Considered Food-Grade For Who? Humans? Or Ecological Lifeforms?

LikeLike